TECHNICAL DATA

| BN_L01 PUMP TYPE | 6 (bar) | 0,1 - 300 (m3/h) | DATA | DRAWING | OPEN |

|---|---|---|---|---|---|

| BN_S01 PUMP TYPE | 6 (bar) | 0,5 - 200 (m3/h) | DATA | DRAWING | OPEN |

|---|---|---|---|---|---|

| BN_S02 PUMP TYPE | 12 (bar) | 0,1 - 180 (m3/h) | DATA | DRAWING | OPEN |

|---|---|---|---|---|---|

| BN_S03 PUMP TYPE | 18 (bar) | 3 - 80 (m3/h) | DATA | DRAWING | OPEN |

|---|---|---|---|---|---|

| BN_S04 PUMP TYPE | 24 (bar) | 0,1 - 140 (m3/h) | DATA | DRAWING | OPEN |

|---|---|---|---|---|---|

| BN_S06 PUMP TYPE | 36 (bar) | 2 - 140 (m3/h) | DATA | DRAWING | OPEN |

|---|---|---|---|---|---|

| BN_S08 PUMP TYPE | 48 (bar) | 0,1 - 140 (m3/h) | DATA | DRAWING | OPEN |

|---|---|---|---|---|---|

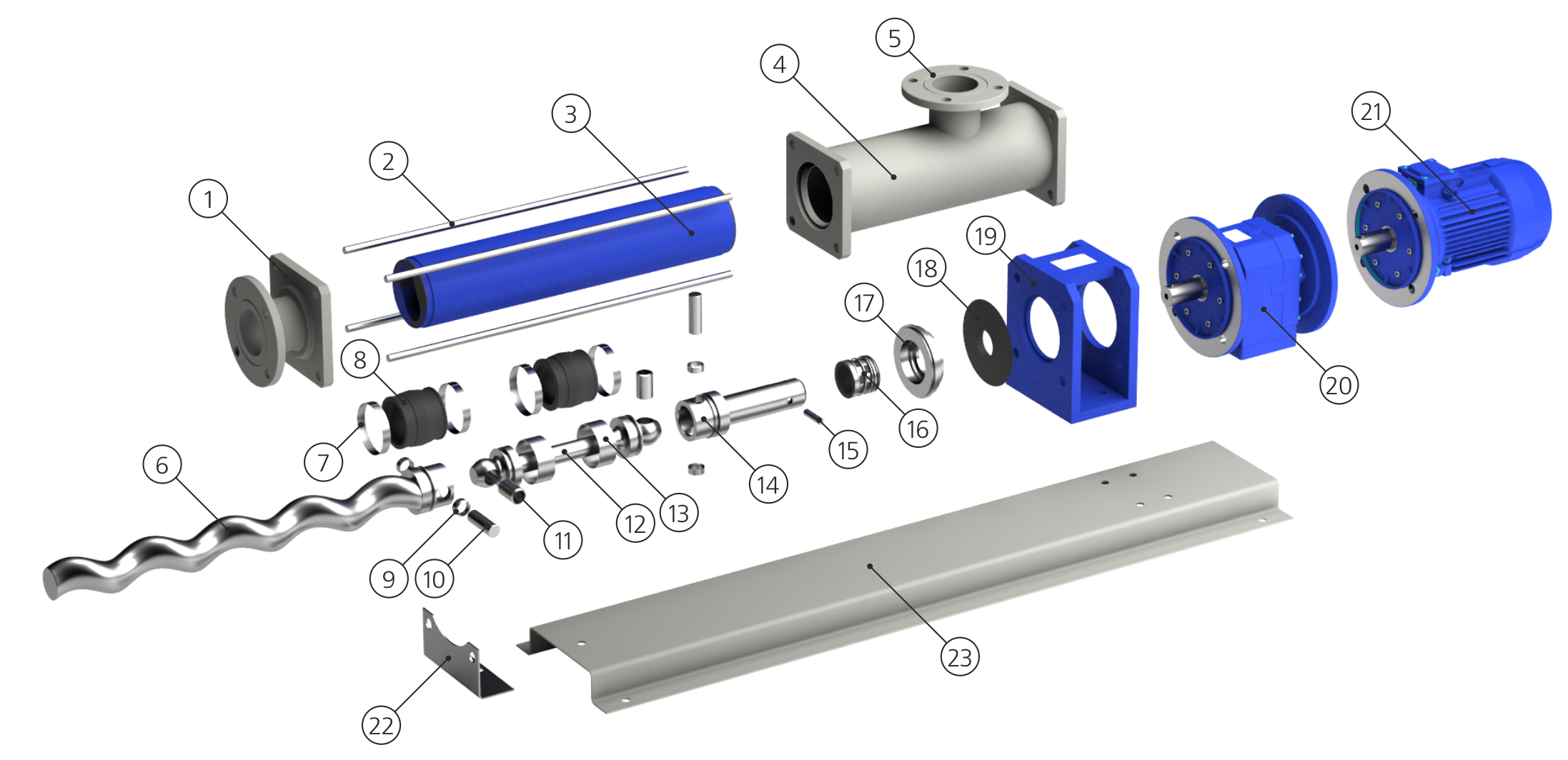

DESIGN

1

Discharge Flange2

Thru-Bolt3

Stator4

Pump Housing5

Suction Flange6

Rotor7

Holding Band8

Boot Seal9

Guide Bush10

Coupling Rod Pin11

Coupling Rod Bush12

Coupling Rod13

Retaining Sleeve14

Plug-in Shaft15

Shaft Pin16

Shaft Sealing17

Sealing Plate18

Retaining Ring19

Lantern20

Gear21

Drive22

Support23

Pump BaseDESIGNATION

| BN | 031 | S02 | H | YY | X | |||||||||||||||||||

| SERIES | ||||||||||||||||||||||||

| BN - horizontal pumps | ||||||||||||||||||||||||

| BV - semi-submersible pumps | ||||||||||||||||||||||||

| BM - dosing metering pumps | ||||||||||||||||||||||||

| BT - barrel drum pumps | ||||||||||||||||||||||||

| MODEL | ||||||||||||||||||||||||

| This parameter defines the diameter and the pitch of the rotor | ||||||||||||||||||||||||

| and determines potential flow rate of the pump | ||||||||||||||||||||||||

| TYPE | ||||||||||||||||||||||||

| L01 - pressure up to 6 (bar) | ||||||||||||||||||||||||

| S01 - pressure up to 6 (bar) | ||||||||||||||||||||||||

| S02 - pressure up to 12 (bar) | ||||||||||||||||||||||||

| S03 - pressure up to 18 (bar) | ||||||||||||||||||||||||

| S04 - pressure up to 24 (bar) | ||||||||||||||||||||||||

| S06 - pressure up to 36 (bar) | ||||||||||||||||||||||||

| S08 - pressure up to 48 (bar) | ||||||||||||||||||||||||

| MATERIAL | ||||||||||||||||||||||||

| H - carbon steel | ||||||||||||||||||||||||

| F - stainless steel AISI 321 | ||||||||||||||||||||||||

| C - stainless steel AISI 316 | ||||||||||||||||||||||||

| DRIVE SHAFT SEALING | ||||||||||||||||||||||||

| Z - stuffing box | ||||||||||||||||||||||||

| Y - single mechanical seal | ||||||||||||||||||||||||

| YY - double mechanical seal | ||||||||||||||||||||||||

| OPTIONS & ACCESSORIES | ||||||||||||||||||||||||

| B - open hopper | ||||||||||||||||||||||||

| S - feeding screw | ||||||||||||||||||||||||

| C - clean-in-place | ||||||||||||||||||||||||

| X - explosion protection | ||||||||||||||||||||||||

| M - mobile platform | ||||||||||||||||||||||||

| V - speed variator | ||||||||||||||||||||||||

| N - frequency inverter | ||||||||||||||||||||||||

OPERATION

SOLTEC Progressive Cavity Pumps is a type of positive displacement pumps that employs an assembly of a single-helical steel rotor and a double-helical resilient stator. Eccentric rotation of the rotor inside the stator forms fixed-size sealed cavities that move along the assembly creating pressure.

The diameter and the eccentricity of the rotor are responsible for the capacity of the pump when the pitch of the rotor is responsible for potential pressure. Usually one pitch of the rotor can develop pressure up to 6 bar. SOLTEC manufactures rotors and stators up to 8 pitches which develop pressure up to 48 bar.

APPLICATION

OIL & GAS INDUSTRY

FOOD & PHARMACEUTICAL INDUSTRY

MINING & EXPLOSIVES INDUSTRY

WASTEWATER & BIOGAS INDUSTRY

PAINTS & COATING INDUSTRY

PULP & PAPER INDUSTRY

INTERNATIONAL (EN)

INTERNATIONAL (EN) EUROPEAN UNION (DE)

EUROPEAN UNION (DE) POLAND (PL)

POLAND (PL) UKRAINE (RU)

UKRAINE (RU)

USA

USA